Drinkwater - The Market Leader in Pipeline Pigging Technology

For more than 30 years, Drinkwater Products has delivered unmatched service and state-of-the-art pipeline specialty products for the oil and gas industry. As a pipeline pigging industry specialist, Drinkwater Products provides a vast selection of everything you need for successful pipeline maintenance.

For more than 30 years, Drinkwater Products has delivered unmatched service and state-of-the-art pipeline specialty products for the oil and gas industry. As a pipeline pigging industry specialist, Drinkwater Products provides a vast selection of everything you need for successful pipeline maintenance.

Pipeline pigging Facts & Application

Pipeline pigging removes harmful substances from pipelines to ensure continuous operation, and in doing so, optimize efficiency by removing any buildup that may restrict flow. Initially, pipeline pigging was introduced as a means to remove dirt and wax deposits in order to optimise proper flow in the pipeline. Modern industries understand the value of pipeline pigging during every phase of a pipeline.

pipeline pigging is applied during:

- construction, to remove debris.

- acceptance testing, to dry, dewater, and gauge.

- during operation, to improve flow efficiency, remove solid and liquid debris and to separate products for applying chemicals, cleaning and batching.

- inspection, to help detect deformations, leaks and dents; record pressure and temperature; measure wax deposition and to sample and map product.

- rehabilitation and renovation, to convert products, and to perform chemical cleaning and coating.

- decommissioning, to remove product, clean pipe-walls, inspect and test for inert gas.

During pipeline pigging, it is crucial to understand the features of different pipelines. Wall thickness and diameter differ, as do distances, areas of operation, pressure, temperature and flow rates.

Contractors follow different codes when designing pipelines, and owners of pipelines have their own philosophy and operating procedures. Therefore, it is important to consider the characteristics of the pipeline when choosing equipment for pipeline pigging.

Premium pipeline pigging Equipment From Drinkwater Products

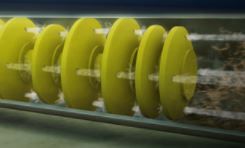

As a recognized industry leader with a lengthy track record in pipeline pigging and pipeline maintenance, Drinkwater Products specializes in corrosion measurement and pipeline pigs.

Get in touch with Drinkwater Products for top quality pipeline products backed by a lifetime of quality customer care;

a wide range of pipeline pigging products and accessories from some of the most reputable manufacturers; and an impressive inventory that ensures the right products are at your fingertips.

Drinkwater Products' services include custom designed pigs, maintenance pigging strategies, and step-up pigging plans. Get in touch with Drinkwater Products for all your pipeline pigs, accessories and services