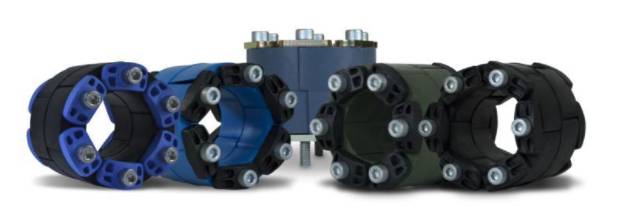

A Link Seal typically consists of a series of rubber links, pressure plates, and bolts that form an airtight, watertight seal between a hole in the core and a pipe when tightened.

A Link Seal typically consists of a series of rubber links, pressure plates, and bolts that form an airtight, watertight seal between a hole in the core and a pipe when tightened.

A perfect hydrostatic seal is always guaranteed with LINK-SEAL, the original modular sealing system.

Any pipe that passes through walls, floors, or ceilings should be sealed permanently. Wall penetrating seals from LINK-SEAL resist aging and provide long-term protection against water, soil, and backfill material.

LINK-SEAL's hydrostatic seal of flexible rubber provides secure, constant pressure around pipes, ensuring error-free installation in 75% less time than hand fitting flashings, mastics, or boots.? Since no caulk or grout is needed, you can begin using your seal immediately without waiting for it to dry.

Pipes and penetrations pass through walls, floors, or ceilings, and it is not uncommon to see link-seals between pipes and these walls, floors, or ceilings. The patented modular seal system can seal any cylinder, as it passes through a barrier, quickly, easily and permanently. A Link-Seal Modular Seal can seal pipe penetrations ranging from 10mm to 3.6m in diameter.

In addition to their inherent resistance to ozone, ultraviolet rays, water, hydrocarbons, and a wide range of chemicals, Link-Seals are also available in liquid, gas, oil and temperature resistant models. Modular seals from Link-Seal can easily be configured to meet a wide range of service conditions with their wide selection of hardware / elastomer combinations. High temperature seals, fire seals (Factory Mutual Approved) and oil resistant seals may be ordered to meet special or unique service applications. Link-Seals are also available for a wide variety of special applications including:

- Pipelines

- Buildings

- Power plants

- A water purification plant

- Platforms for offshore production

- Compressor stations

- Overpasses

- Penetrations of the interior and exterior walls

- Piping for fire protection

- Flow lines

- Conduit for electrical power

- Instrument lines

BENEFITS AND FEATURES

Link-seal belts are installed by positioning them between the pipe and annular wall. A proper tightening sequence is followed then to tighten the seal. After installation, the link-seals provide a pressure-tight and secure seal by expanding radially.

- It takes 75% less time to install than lead-oakum joints, hand-fitted flashings, mastics, or casing boots.

- It can be installed during the pipe operation, so the plant does not have to be shut down.

- With a pressure rating of 20 psig (40ft of head), it surpasses the performance requirements of most applications.

- Designed to function as a permanent seal. A seal's components are specially formulated to resist aging, sunlight, water, and a wide range of chemicals.

- A two-part zinc dichromate and a proprietary corrosion inhibiting coating are standard for fasteners. The highest degree of corrosion resistance is available in 316 stainless steel.

- NSF 61 and Factory Mutual Fire Approved materials are available. They are also approved by a variety of federal agencies, associations, code groups, laboratories, and organizations.

- This product is made in a facility that is certified to ISO 9001.

- Various hardware options are available to match performance characteristics with service conditions, including 16 colored sizes of EPDM, Nitrile, and Silicone elastomers.

- Resistance to temperature (-500C to 2040C) and chemical attack (corrosion).